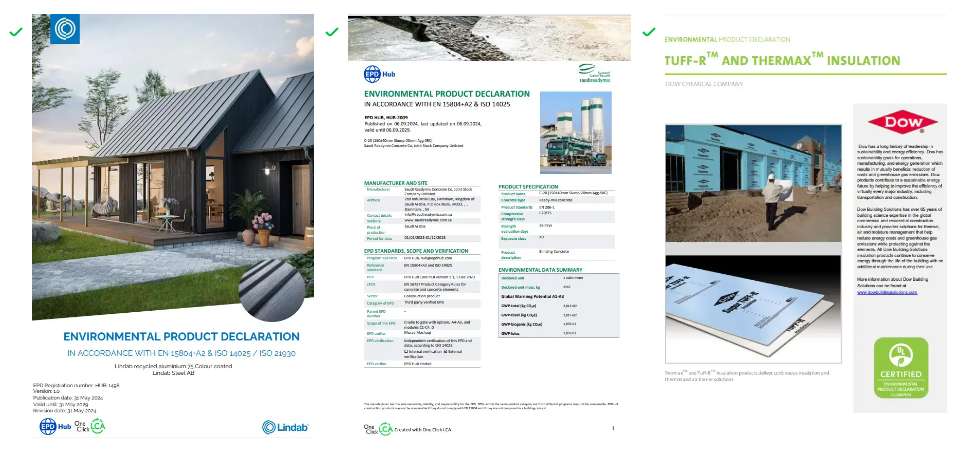

EPDs provide valuable insights about a product’s environmental performance at a glance. However, EPDs may vary in appearance depending on the Product Category Rules (PCRs) they follow and the program operator that publishes them.

An EPD covers the following information:

- General information: Includes details about the manufacturer, the product, the reference standards, and the EPD scope.

- Product lifecycle information: Provides details on the lifecycle modules covered by the EPD.

- Life-cycle assessment (LCA) methodology: Explains the methodology used to assess the life cycle.

- LCA background information: Includes assessment of data quality and interpretation of results.

- Environmental impact data: Presents data on the environmental impacts identified in the assessment.

- Verification statement: Contains the statement verifying the accuracy and validity of the EPD data.

To effectively compare different EPDs, or to go through the most important information of an EPD, you should focus on these five key points:

-

Reference standards used for the EPD

The reference standards used for the EPD are the official guidelines and scientific methods followed to calculate and report the environmental impacts. These standards ensure that the EPD is produced using reliable, recognized methodologies, so the data is comparable across similar products and is accepted in the industry. Construction EPDs are based on the ISO 14040/14044, ISO 14025, EN 15804 or ISO 21930 standards. In the example EPD below, you can find this information under EPD Standards, Scope and Verification:

-

Period of validity

The period of validity refers to the time frame during which the EPD remains accurate and relevant. EPDs are based on data that can change over time due to shifts in manufacturing processes, energy sources, or supply chains. This period ensures that the environmental impact data provided is up-to-date and reliable for a specific duration, 5 years for third-party verified EPDs. After this period, the EPD should be reviewed or updated to reflect any changes. This example EPD below, has validity for 5 years:

-

Verification

It’s important to ensure that an EPD is third-party verified. This means an independent organization has reviewed the data and processes used in the EPD to confirm its accuracy. Third-party verification adds credibility to the EPD, showing that the environmental impacts, such as carbon emissions, are calculated properly and are based on reliable information.

-

The environmental data summary

The environmental data summary provides key information about the product’s environmental impact. The main components to look out for include:

- GWP-total (global warming potential), A1-A3 (kg CO₂e): This measures the product’s total carbon footprint, showing how much it contributes to climate change. It accounts for all greenhouse gas emissions from stages A1 to A3 (raw material extraction, transportation, and manufacturing).

- GWP-fossil, A1-A3 (kg CO₂e): This focuses specifically on emissions from burning fossil fuels during production. It’s a more detailed look at how much fossil energy is consumed and how much CO₂ is emitted as a result.

-

Declared unit

You can find the the declared unit under product description. Declared unit is the reference point for measuring environmental impact. It’s like saying “calories per serving” when describing food nutrition. For construction products, this might be measured in terms of weight (e.g., kilograms of concrete) or volume (e.g., cubic meters of a material). The declared unit standardizes the environmental data so that the impacts, such as emissions or energy use, are compared on the same basis across different products.

By checking these elements, you ensure the EPD is current and that you’re examining the intended product. This approach helps you understand the characteristics for comparison, including type, impact, and unit.

How to compare different EPDs

Manufacturers, architects, and engineers often need to compare EPDs when selecting suppliers or choosing products with the lowest environmental impact for their projects. To make an informed decision, it’s essential to focus on key factors that reveal the most important details of their environmental performance. These factors will help ensure a fair and accurate comparison between EPDs:

1. Functional unit

Products should be compared based on the same functional unit to ensure that their environmental impacts are measured equivalently. If the functional units differ, the comparison will be skewed.

2. Scope of the EPD

EPDs can have different life cycle stages:

- Cradle-to-gate: Covers extraction of raw materials to manufacturing.

- Cradle-to-grave: Covers the entire lifecycle, from extraction to disposal.

- Cradle-to-cradle: Includes recycling at the end of life.

Ensure the products being compared use the same life cycle stages in their EPDs to avoid inconsistencies.

3. System boundaries

Understand what is included in each EPD. Some may cover additional or fewer processes, such as transportation, energy use in operation, or end-of-life disposal. The system boundary should be consistent to ensure all aspects of the product’s lifecycle are accounted for similarly.

4. Environmental impact categories

The environmental impact categories are the same and comparable. Ensure that both products report on the same categories to make meaningful comparisons. Common categories include:

- Global Warming Potential (GWP)

- Ozone Depletion Potential (ODP)

- Acidification Potential

- Eutrophication Potential

- Photochemical Ozone Creation Potential

5. Data quality and source

Verify the quality and sources of data used in the EPD. Primary data (from actual manufacturing processes) is generally more reliable than secondary data (from databases or literature). Products with well-documented, high-quality data are easier to compare accurately. You can find this information in the ‘LCA background information’ section.

6. Geographical and temporal differences

Geography can influence the environmental impact of a product (e.g., energy mix in manufacturing locations or transportation distances). Similarly, temporal differences (the year the data was collected) matter, as technologies and regulations change over time. Ensure both products are analyzed in the same geographic context and time period.

7. Assumptions and allocation methods

Some EPDs make assumptions about things like energy use, transportation distances, or recycling rates. Be sure that similar assumptions or allocation methods are used when comparing products. You can find this information in the ‘LCA background information’ section.

8. Certification and verification

Ensure that both EPDs are verified by an independent third party to ensure the data is credible and consistent with international standards (e.g., ISO 14025, EN 15804).

9. Product lifespan

Some products might have different expected lifespans. Comparing them on a per-year basis (e.g., GWP over 50 years of service) can provide a clearer picture, especially if one product lasts significantly longer. Find this information the product description.

10. Material composition and recyclability

Consider the materials used and their potential for recycling or reuse. A product with a high environmental impact during manufacturing might offset this by being highly recyclable or having a long lifespan.

By focusing on these factors when comparing different EPDs, you can ensure you’re comparing products in a way that reflects their true environmental performance, helping you make more informed and fair eco-friendly choices.